The project starts with the battery box. Pretty basic stuff, 3/4" CDX plywood screwed and glued. I chose CDX for the outdoor-rated glue since I knew the box would be carpeted anyway, plus it was $18/sheet instead of $45/sheet for the nice birch stuff!

The design of the box looks a little odd at first, but the rear edge of the box actually supports the forward edge of the bed platform, hence the extra height. Everything is designed to maximize space, so the forward part of the box nestles right up to the back of the bench/bed and part of it will be UNDER the seat-back as it folds back. The cutouts on the front (left) side of the box are to clear the movement of part of the bed mechanism. The upper notches are to clear the "arms" of the bed as it folds down. The inner "walls" of the box provide strength for the tie-down system (more on this below) and form the inner battery tray that helps keep things from moving around. In this photo I'm trial-fitting the Group 31 AGM battery, only to find that it's just a hair tall with the top posts, so I ended up switching to a Group 34 battery.

As I said, the inner walls of the box actually provide the strength for the tie-down system. In this shot the box is on its back. The fasteners for the hooks and eyes go all they way into the vertical dividers, making everything plenty strong.

Here's the back of the van where the box snugs up against the bench seat. My conversion van bench/bed is mounted to the floor in between where the 2nd and 3rd rows would have been. I utilized the existing attachment pins in the floor for the original 3rd row bench to mount the box. The hooks you can see in the above photo grab onto the aft pins in the floor, and then shackles and turn buckles tie into the forward pins to pull the box forward and down, making everything rock solid.

The inside of the box was then coated in brush-on bedliner, then everything was carpeted with a pretty decent match for the OEM floor/lower trim carpeting.

The inside of the box was then coated in brush-on bedliner, then everything was carpeted with a pretty decent match for the OEM floor/lower trim carpeting.Next was to weld up the support legs for the back portion of the bed platform. These legs ended up spaced about 16-1/2" on center, but the platform is 29" or so deep, so I made the tops of the legs into "Tees" so that there wouldn't be a long unsupported span in the fore/aft direction.

The bottom of the legs were tapped for threaded riser bolts so I could adjust the final height to level everything out. The legs attach to the platform with knob-headed screws into teenuts in the platform. I wanted a completely tool-less way to remove the platform and break it down completely flat for easy storage in my garage when not in use.

The platform attaches to the battery box with a couple of removable-pin hinges. Again, a tool-less way to attach the platform to the box, but it serves a more important purpose also:

The whole platform hinges up to allow easy access to the stuff underneath. In particular, I wanted to make sure I didn't block access to the jack compartment on the passenger side (right corner of photo). As it stands, the rightmost leg sits directly in front of that access panel. Eventually, I'll probably add a cam-lock strap or chain at the rear edge of the platform to engage with the stock D-rings at the rear of the cargo area, which will hold the platform down and keep the cargo underneath from moving in case of accident.

The whole platform hinges up to allow easy access to the stuff underneath. In particular, I wanted to make sure I didn't block access to the jack compartment on the passenger side (right corner of photo). As it stands, the rightmost leg sits directly in front of that access panel. Eventually, I'll probably add a cam-lock strap or chain at the rear edge of the platform to engage with the stock D-rings at the rear of the cargo area, which will hold the platform down and keep the cargo underneath from moving in case of accident.When the platform is down, there's just enough space between the legs for three tall Rubbermaid containers, or two tall containers and one short one with my Coleman stove on top, or two containers and a 7-gallon water jug. Not as fancy as some of the great drawer systems I've seen on the epic storage system thread on Expedition Portal.com, but this system is flexible, and more importantly, it lets me easily move the packed bins back and forth from the garage, which makes packing for trips and unpacking afterwards super easy.

With the addition of some firm 2" foam, the bed platform mates up perfectly with the bench seat as it lowers into a bed, making the sleeping area roughly 56" by 72". I bought the slip cover material at Ikea, and it was sewn by my Mother. I would have done it myself (hey, a sewing machine is a power tool too!), but I was running out of time prior to Overland Expo 2011, and Mom was eager to help. Admittedly, she did a much better job than I would have. Thanks Mom!

The only bad news here is how snug the platform is to the rear doors. I plan to build some drop tables onto these, so I'll have to modify the platform at a later date to provide a little clearance. Oops!

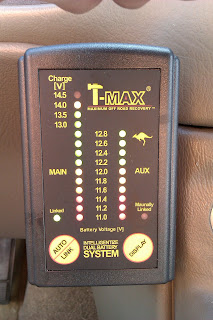

Getting the battery box built meant I could also install the house battery and split-charging system. For the split-charge controller, I gambled on the T-Max system from Summit Racing. Definitely not as full-featured as the offerings from IBS or National Luna, but way way cheaper, and budget was a consideration here. If or when it fails, I'll consider upgrading, but for now it's working great. I mounted the display/control interface on the lower dash next to the doghouse on a custom bracket. I do actually like the display - during normal running it only lights the charging LEDs at the top left, you can hit "display" to see the state-of-charge on the main (starting) and aux batteries at any time. I like that it's completely dark when the engine is off, since the LEDs could be annoying at night.

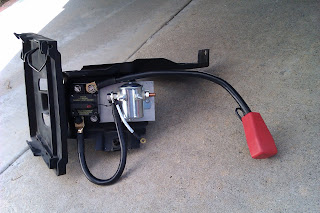

The other half of the T-Max system is the massive solenoid. I used some scrap aluminum to make a mounting plate that I riveted to the bottom of the mounting bracket that holds the starting battery and ECU mounting frame in the engine bay. The block on the left is one of two 150A breakers (one at each end of the run of cable back to the box in the rear). I used extended side posts to tie the extra power and ground cables onto the main battery.

The main run of cables from the engine bay to the battery box was made by cutting up a new set of 2-gauge jumper cables. I like using jumper cables because they're fairly flexible and inexpensive compared to buying other big cables by the foot. In this case I opted to separate the positive and negative and cover each with a tough outer braid. For the entire run these are fixed to the van BODY, and always above the sub-frame because I know the body-to-subframe distances will be changing soon when I install the lift kit (which includes body-lift pucks.)

The cables enter the interior just aft of the fuel filler and stay behind the plastic interior trim (removed in this photo) until they enter the battery box where they connect to the second breaker, fuse panel, and house battery.

For now I'm just running my Edgestar fridge and house lights (rewired the vans dome and map lights to take power from the house battery), but eventually the HAM radio and a few other goodies will also take power here.

Read More...